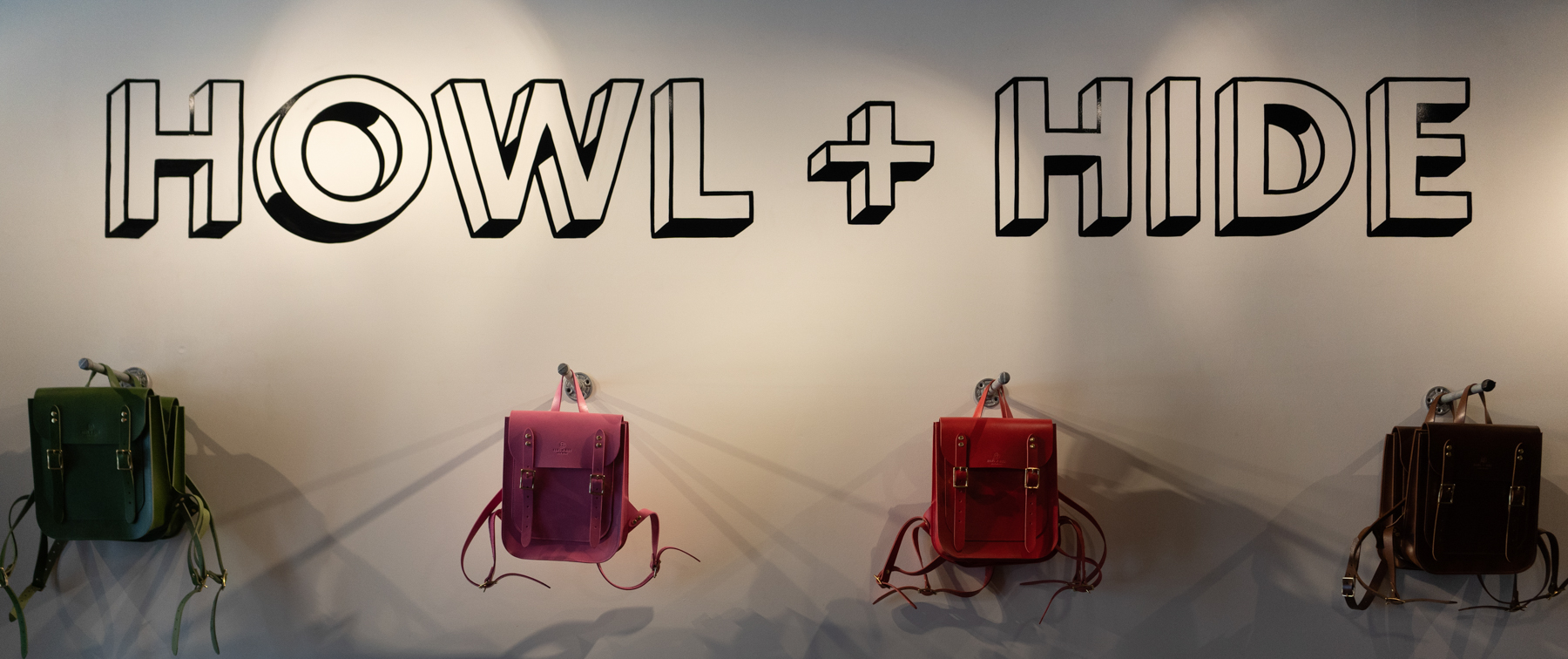

Interested in making leather goods or simply becoming a more profitable business as a maker? Check out the Maker of The Month Q+A below! We interviewed Christian Resiak, who owns Howl + Hide, a quality leather company based in Indianapolis.

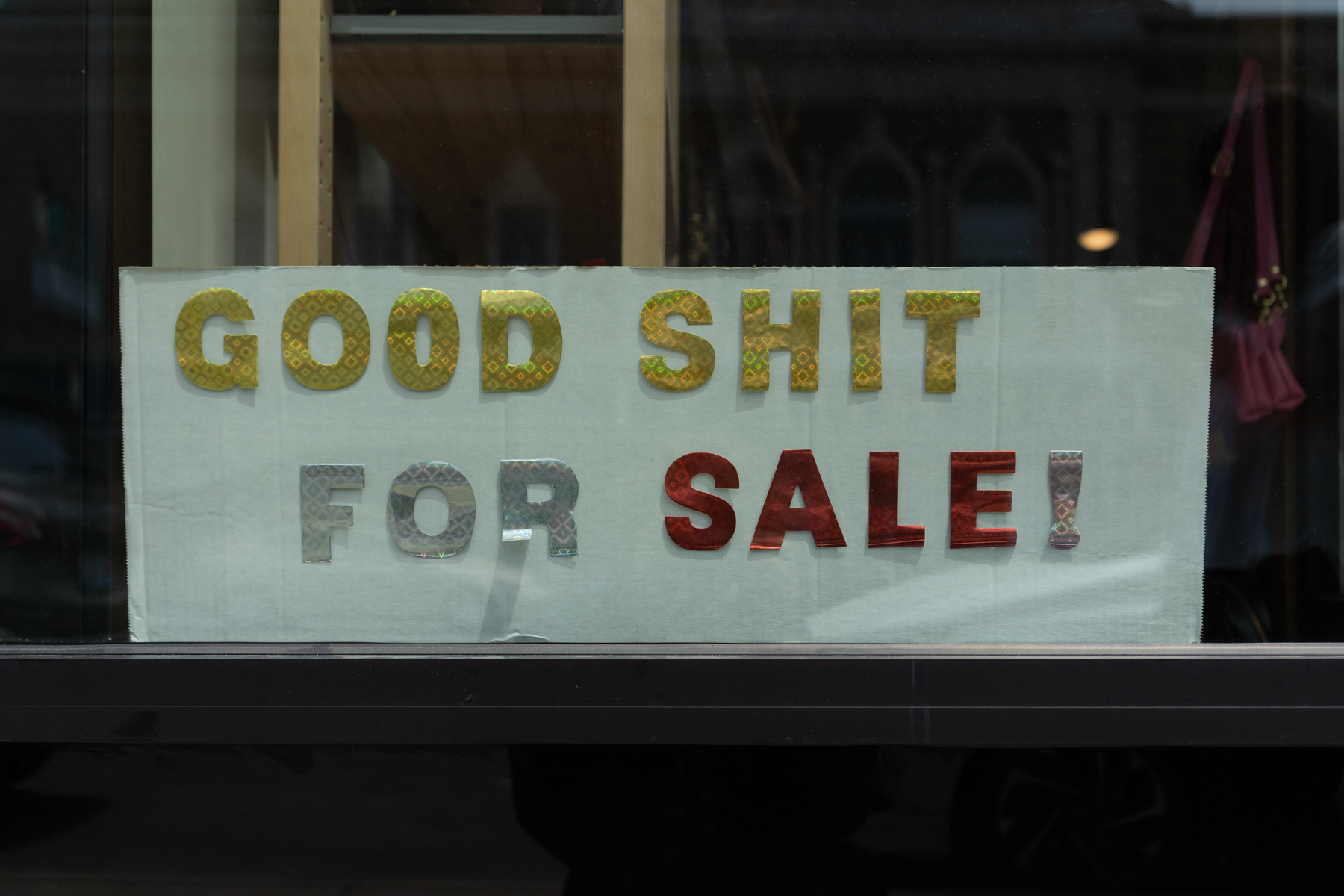

We headed over to their new flagship location on Virginia Ave to get a look at a new installation, chat with Resiak, and check out the behind the scenes production area. Everything for sale at Howl + Hide is made in house by a team of eleven. You can smell the quality when entering their store. All of their bags are gender neutral and come in natural tones or some super funky fun colors like pink, blue, red, and green. In the store you can buy clothing, accessories, wallets, and even get a haircut at Wild’s Barbershop upstairs. The atmosphere is fun and laid-back, yet sophisticated. It makes sense, considering Resiak is redefining what it means to be a quality maker and designer in the Midwest.

Cory Cathcart: What do you make and how long have you been doing it?

Christian Resiak: I started in 2014 and we’ve been kicking it ever since. Specialty and leather bags are the biggest focus. We dabble in some canvas and smaller goods. Bags and accessories have been our big thing. We’ve done a lot; but over the course of the years, we’ve refined it to what we like to make and what the people like us to make.

CC: Do you have any other retail locations?

CR: This is our only location. There was actually a build up to this. We were at the PATTERN workshop on Mass Ave for eight months in 2015. Pretty much from August to February, and then we moved to our State and English location, which was across the street from our old spot. We were in that for two years, then moved to our old location on English, which we loved. And then two years ago, we opened up a pop-up in Carmel, which was a really, really well thought out plan. We knew that of all our in-state orders, that zip code was the bulk of them that we were shipping to. So we opened up a temporary holiday pop-up there. It was really just one big test to see if we could do this and it was super successful. We carried other brands, it was about 1,500 square feet solely for retail. We learned a whole lot. Then last year I knew, hitting it hard, that I needed to find a space that was a really shoppable space and allowed us to be able to do what we’re doing. We signed on to this last April, did the whole build out, and then we opened in November of last year.

CC: Do you sell anything online?

CR: Yeah. There’s a big chunk that we sell online. Now we’re shipping all over which has been really nice. But after opening this, retail has become booming for us because we’re right here. We’re moving towards half online and half retail.

CC: What influences you?

CR: Classic but with a twist, I guess. Everything that is produced out of here is pretty much just in my brain. It took a long time–like four years–to figure out what the core products were going to be. For the last three years, we’ve been holding true to our catalog of styles that we have. Really it’s taking traditional leather working–like our saddlebag for instance, it’s a super classic silhouette–but doing it in a pale pink, a red, a green, a blue, which is not necessarily seen.

CC: What comes first for you, the materials or the concept?

CR: In my process it’s the materials. I’m not a big drawer. I’ll sketch something out if I’ve been struggling with it. I mostly think of dimensions and color. Then I’ll make it. Sometimes that concept that was in my brain didn’t necessarily work out, whether that bag is too tall or too wide or too big. Then I pull from there, and tweak the things. Really the material for me is what drives the conceptual process.

CC: What would you say is your staple bag and what inspired it?

CR: That bag is the Penny. My biggest thing was that I wanted to make an affordable leather bag with a lifetime warranty that I knew would consistently sell. It has grown to be a staple. You can wear it multiple different ways, you can wear it over one shoulder, you can use it as a crossbody, or you can use it as a waist bag. Within my process I tried to think of being a gender fluid store and really ringing true on that. I don’t conceptualize stuff based on gender necessarily. We want to bypass that notion and that mindset.

CC: Can you describe the creation process and what your favorite tool in the process is?

CR: It’s changed now quite a bit since we have the staff that we have, and we’re putting out the amount of products that we’re putting out. Before, everything was hand cut, hand sewn. I held on to that for as long as I could. Then I understood that in order to build a brand, especially in the Midwest, we have to be able to streamline the process. A lot of the machinery that we’ve added has become really crucial to the end result. For me, if I’m looking at a piece of leather and I’m about to make something, I’ll typically hand cut it and then that first item is the sample, per se, to where that’s all hand cut. What we’ll do from there is we’ll have custom clicker press dies made. My favorite tool in the back is our clicker press. It’s crucial to the process. The saddlebag, for instance, before we’d have to cut out the rectangles and the square. Then we’d have to round all the corners and then add the hardware slots all by hand. Now we just slide the piece of leather into our clicker press and the clicker dies are essentially one big leather cookie cutter. Then we just press two buttons. It forces pressure down and it cuts it all out and rounds the corners. It’s been super nice, especially to teach others the craft. Everything is going to be perfect throughout the process, so that’s probably my favorite piece of machinery that we have in the shop.

CC: What is something that you’ve made that you’re most proud of? What’s special about it?

CR: In terms of quantity, we’ve got one client that we work with that we developed a run of luggage for. It was really cool to see based on the team effort and seeing a lot of those bags come to fruition. I think my all time favorite collection that we did was a collaboration with Wilson baseball gloves. The coolest part about it was that they reached out to us, and we had just launched the Keystone Knapsack. They reached out to us and they were like, “Hey, we love this style bag. We want to get it for all of the Olympic softball players that use a Wilson glove.” So we got to make a run of that. We made custom leather flags that represented what countries those players came from. It was super cool. It was awesome to watch that come to fruition. It was also the last collection that we made in our old shop, which was a beloved store, all 1,500 square feet of it. That was the coolest, most proud moment that I had.

CC: What advice would you give to aspiring makers of any sort?

CR: Be about it. I mean, really. I’m sure that so many people will be like, “Christian talks a big game,” and I one hundred percet talk a big game. One of my biggest things about talking that big game is bringing that to fruition. If you’ve got an idea, let’s go. Do anything that you can to make it work. That’d be my biggest piece of advice.

CC: What is one thing that you think the creative or design community in Indianapolis can do to grow an audience?

CR: Removing the boundary. I say that because a lot of people will look at the Howl + Hide logo; it says “Howl + Hide Made in USA” and any times folks are like, “Why does it say made in USA and not made in Indiana?” The goal for me is to ship coast to coast, or around the world. If somebody’s ordering a bag in, I don’t know, Vermont, they don’t care that it says made in Indiana. It’s cool! It’s so sick that it’s made here. It’s about thinking long-term, bigger picture, rather than basing your idea on where you’re physically located. We’re proud of that, and most people don’t know that every one of our bags, minus the Penny, is named after a different Indianapolis street. That to me is something as an artist or as a designer is super important, but at the same time who am I to judge what you do? It’s the same thing as if you are selling only to women. You cut out half of the population by just selling to women, right? But again, to each their own.

CC: What makes your pieces unique?

CR: It’s a lot to do with the heart and soul of Howl + Hide that makes it different. Whether these competitors are in New York or here, if you’re making a tote bag, it’s a tote bag. There’s a lot of things that you can change about it, but when it comes down to it, the category of bag that it is, is a tote bag. So if you make a tote bag, just make a little different. That’s what I always try to do. It took us a very long time to find the color wheel leathers: the green, the pink, the red, and the blue. It’s a vegetable tanned leather, which is a very long tanning process and the quality is very high on vegetable tanned leather product. Historically it’s done in brown, natural, and black. We finally found a source that has full drum dyed vegetable tanned leather in crazy colors. So that’s what is going to stand us apart.

CC: What has been the most rewarding memory of this business?

CR: This. This store. We bust our ass, you know. This is a lot of mistakes, a lot of learning. It felt like when we opened that this is Howl + Hide in Indianapolis. This is our flagship store. We make everything here. It’s big, it’s beautiful, it’s in the heart of it all. It’s a reintroduction of who we are into the community, even though we’ve been doing it for quite some time.